Consulting Services

Our consultants have many years of in-depth, professional experience in process design, startup, troubleshooting, and operations. We are consulted by other consultants and we are renowned for our unmatched perspective for innovatively eliminating process bottlenecks. Come to us for a complete Unit Review, for well thought out advice on problematic operations, and for resolving issues with an underperforming process, optimizing unit performance, acting as expert witness in legal disputes and litigation, and providing you with first-rate simulation tools uniquely tailored and customized to your specific needs. If poor plant performance is keeping you awake at night, let our consulting group help you bring performance back up to where it should be.

Besides providing top-notch, engineering consulting services, we design and build the computer models engineers actually use. We can develop customized user-friendly software unique to your operations or to a special piece of equipment to let you analyze, troubleshoot and design on a rational, reliable basis, and help you get the very best from your equipment or process, both operationally and commercially.

OGT offers Consulting Services in Gas Treating, Sour Water Stripping, Caustic Treating, SRU, and TGTU operations.

Services include

- Full Unit Reviews,

- Troubleshooting,

- Optimization,

- Equipment Design & Analysis,

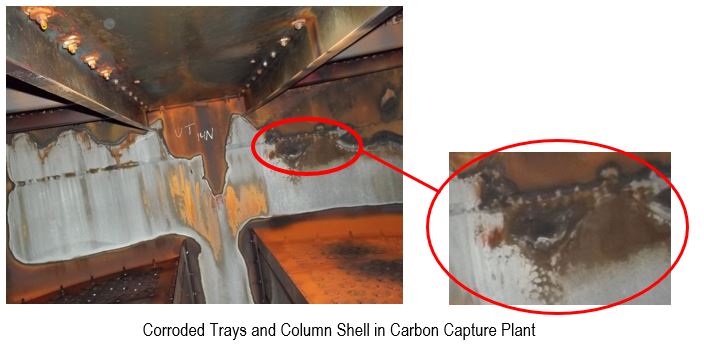

- Corrosion Analysis and Mitigation,

- Custom Analytical Tools,

- Simulation Software Development, and

- Autonomous Unit Monitoring.